Impure metal used to make a gear in the proprotor gearbox of a CV-22 caused it to fail, leading to a mishap and emergency landing in November 2024 that resulted in nearly $2.8 million in damages and a brief operational pause for the entire Osprey fleet, according to a new Air Force report.

The accident investigation board report, released by Air Force Special Operations Command on Jan. 9, details a slightly different part failure than the one that led to the deadly crash that killed eight Air Commandos in November 2023—but traces it back to the same issue of impurities in a specific steel alloy that have led to more than 20 cracked gears in V-22s over the past two decades.

None of the crew’s four Airmen were seriously injured in the 2024 mishap, which occurred near Melrose Air Force Range in New Mexico. Investigators determined that heightened safety procedures and risk awareness created a culture of “’getting the aircraft on the ground’ in an emergency” in the 20th Special Operations Squadron, to which the CV-22 was assigned, helping the crew make better decisions during the mishap.

Yet the report also details growing anxiety among Osprey aviators as the aircraft continues to be the focus of safety concerns.

“Interviews revealed that [squadron leadership] had concern that this event and others had created uncertainty in some 20 SOS members regarding the safety of the CV-22B airframe,” the report states. “Despite this, leadership assessed overall unit confidence in the aircraft as high, but aircrew (especially the Special Mission Aviator (SMA) community) were stressed due to the many changes the CV-22B community had experienced in the previous 2-3 years and the number of mishaps that had occurred in the past two years.”

Officials continue to insist the V-22’s poor safety reputation is unearned and not based on actual flight data.

What Happened

The mishap occurred Nov. 20, 2024, as the Air Force was executing a “return to flight” campaign for the Osprey following its grounding related to the fatal 2023 crash. One of the pilots needed qualification and training coming out of the stand-down, and the sortie was proceeding smoothly with the aircraft just a few hundred feet above ground level when in the span of just a few seconds, the crew received notifications that the left proprotor gearbox’s oil pressure was falling and the left gearbox and engine were both failing.

Within 13 seconds, the crew decided to land. When one of the Osprey’s engines fails, the other provides power to keep it flying, and the aviators were able to take the aircraft down for an emergency landing in a cattle pasture.

The CV-22 landed with more forward speed and rate of descent than recommended for a low-visibility approach, but those recommendations assume both engines are working and the crew did keep the rate of descent below the maximum allowable limit.

The aircraft’s landing gear slammed into the ground, causing the nose to rotate and drag one of the landing gear assemblies while the other bounced. One of the flight engineers was thrown from his position, but the situation was stable enough that the crew was able to execute a slightly modified normal shutdown of the aircraft.

“[The crew’s] responses to the emergency mitigated damage to the aircraft and injury to the crew, despite not fully understanding the cause of the problem,” the report concludes.

The Air Force, along with the Marines and the Navy, issued an operational pause for the Osprey fleet after the mishap that lasted until Dec. 20, 2024.

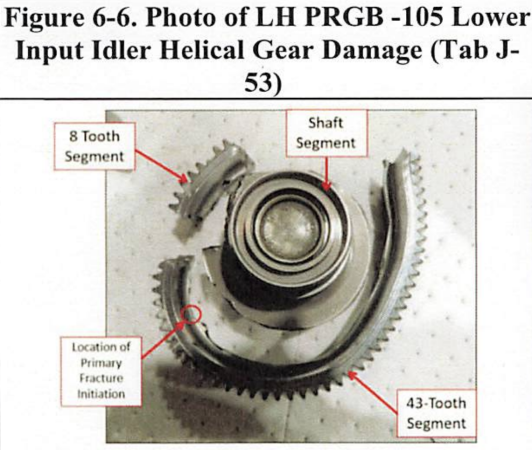

Investigators determined the main cause of the crash was the “catastrophic failure of the … Lower Input Idler Helical Gear” in the lefthand proprotor gearbox.

Chemical analysis found impurities in the metal of the gear around its “web”—the portion of the gear between the rim and the main shaft. Small amounts of aluminum, calcium, and oxygen caused an impurity or inclusion “measuring 0.055 inches long by 0.011 inches wide.”

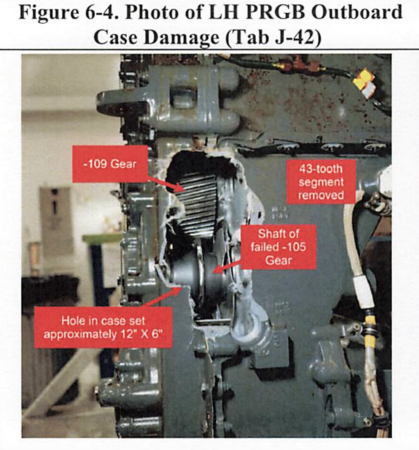

Even small impurities can cause excess fatigue, and investigators found that the gear had cracked, causing a portion of the rim to become dislodged. That eight-tooth section “ejected” through the shroud covering the gearbox, creating a 12-by-6 inch hole. The remaining 43-tooth section of the Gear “was deformed into a ‘J’ shape and wedged in the hole,” investigators wrote.

Other gears exhibited minor signs of damage from the destruction of the failed gear.

“The hole caused a rapid loss of oil pressure in the [gearbox]. Simultaneously, the rapid destruction of the … gear caused damage to the drive gear of the [gearbox] oil pump,” the report states, adding that the failed gear also caused the engine turbine to overspeed because of a “no-load” condition.

Materiel Issues

A rash of mishaps in recent years have led the Air Force, Navy, and Marine Corps to study the V-22, culminating in a comprehensive review by Naval Air Systems Command released in December 2025.

At the heart of the review is the aircraft’s unique proprotor gearbox, which allows it to fly like a helicopter or a plane. The complexity of the aircraft’s transmission has been a known issue since it debuted in the 1990s. The engine, weight, and vibration have to rotate, which puts enormous stress on the gears and driveshaft.

The Navy review determined there were two main gearbox issues:

- Hard clutch engagements, when the clutch slips and reengages, causing massive swings in torque and making the aircraft difficult to control

- X-53 steel alloy material impurities, or inclusions, leading to part failures. Since 2006, there have been 22 instances of gears cracking because of inclusions, the report states.

Investigators looking at the November 2024 mishap note that latter issue, writing that “it is important to understand some of the history of X-53 steel, its use on various components in the V-22 Osprey, and documented cases of material failure due to material inclusions.”

In most cases, investigators noted, failures of gears made with X-53 steel results in metal chips. The Osprey actually has a system designed to detect and clear those chips, which were the cause of the November 2023 crash that killed eight Airmen—that crew received six chip burn warnings that indicated the aircraft was no longer burning off the stray metal pieces.

Yet there were no chips in the 2024 incident. Rather, the gear cracked. Investigators wrote that V-22 program officials have known since 2014 that “identified impurities” in X-53 steel “can result in stress concentration resulting in cracks in the gear structure. Cracks in gears can result in pieces breaking off and damaging other gearbox components.”

That issue came back up again in a January 2024 safety risk assessment which noted that “a nonchip producing failure mode of a crack or hole in the [gearbox] case set which could result in rapid loss of oil and the seizure of gears and failure to transfer power to the proprotor system,” the accident report notes.

Despite this, the metal used for the gear that failed in the November 2024 mishap “conformed to all material specifications at the time of production and inspection,” the report states. Even if it had been flagged, that specific kind of gear was not designated as a “critical single point of failure component,” meaning officials believed the Osprey could keep flying even if it broke.

In conclusion, investigators faulted the gear as “poorly designed” and noted that a plan is already in place to improve the V-22’s gearboxes, including a new “triple melt process” for the X-53 steel “projected to reduce risk to individual parts and the [gearbox] by up to 90 percent.”