John F. McDonnell, the former CEO and current chairman of McDonnell Douglas Corp., once likened his company’s new C-17 airlifter to a problem child who straightened himself out. “If a $100 million write-off is like wrecking the family car, then the C-17 wrecked the car ten times,” he joked. Then, after causing enormous grief, this child “surprised everyone by going on to graduate from college with highest honors,” Mr. McDonnell added.

The C-17 has, in fact, won important trophies and accolades, but the recognition that really counted came last November in a statement from the Pentagon’s Defense Acquisition Board (DAB). The panel, after a rigorous evaluation, concluded that the C-17 program had fully overcome serious delivery, quality, and cost problems.

The Air Force, it said, would be cleared to spend an estimated $18 billion to purchase eighty more of the advanced C-17 transports, raising the projected fleet total to 120.

“This is a ‘good news’ story,” said Deputy Secretary of Defense John P. White in announcing the panel’s findings. “The C-17 program was in deep trouble two years ago, and I would like to commend the Air Force-particularly the acquisition staff and field acquisition personnel-for creating strong airlift options for the department, options that we did not have two years ago.”

The decision to press on with the C-17, however, was not made in a vacuum, focused solely on whether the program had been able to steer away from its troubled course. Rather, the choice to build the full C-17 fleet boiled out of a cauldron of studies, requirements, capabilities, missions, and economic realities affecting military airlift beyond the 1990s.

More Decisions to Come

Though the future of the C-17 has been decided for now, the airlift debate is not yet over. Other decisions to be made in the next several months will also have significant implications for the long-term strength of Air Mobility Command’s airlift force. That, in turn, will determine whether the Air Force will be able to provide the airlift required to carry out national strategy.

In 1993, problems with the C-17 had become the stuff of daily headlines. Then Under Secretary of Defense for Acquisition John M. Deutch (now director of Central Intelligence) said that terminating the airplane was a “very tempting” option. However, everyone knew that the C-141 Starlifter fleet was deteriorating rapidly and had to be replaced soon. The C-17 was in trouble, but there was no guarantee that a new start would fare any better.

Even so, Secretary Deutch put McDonnell Douglas and USAF on notice that he would halt production at forty airplanes if the Globemaster III couldn’t be “put right” within two years. He set the October 1995 DAB meeting as decision time.

Secretary Deutch presented McDonnell Douglas with a “nonnegotiable” omnibus settlement that required the company to drop $1.2 billion in claims against the government and put up another $456 million to improve management and quality on the program. In return, the Air Force had to find $348 million to settle program-related claims and rigorously flight-test the airplane. It had to relax some of the most extreme performance requirements for the C-17, which were deemed unnecessary and expensive to attain.

There was a further catch: If the Air Force and McDonnell Douglas failed, USAF would have to buy an “alternative” airlifter to meet cargo requirements [see “Off-the-Shelf Airlift,” February 1995, p. 32]. Secretary Deutch said the deal offered the Pentagon “the opportunity to fix the C-17 but does not hold us hostage.”

For the company, this was a turning point. The omnibus agreement was “a major part of the turnaround,” said McDonnell Douglas Vice President and Deputy Program Manager George G. Field. “They told us, ‘Clean up your act,’ ” he said, but the omnibus agreement “put a limit on it . . . and set parameters” for how the C-17 would be judged. He explained that the agreement “cleared the decks” for a change in the dealings between the Air Force and McDonnell Douglas, which had degenerated into a blame-and-counterblame, adversarial relationship.

Almost at once, the attitude between the two parties turned “very productive,” Mr. Field reported. That led to the creation of Integrated Product Teams, in which service and company officials worked together at all levels, focusing on quality and meeting the schedule.

Well before the two years were up, the C-17 program pulled out of its nose dive. The contractor began meeting-then beating-the delivery schedule. The aircraft itself was performing in the field “beyond our expectations,” said Air Force Chief of Staff Gen. Ronald R. Fogleman.

Last summer-with press and various government agencies keeping a keen watch-the C-17 passed a grueling reliability, maintainability, and availability evaluation with ease. It was an acid test that judged the airplane by criteria usually applied to “a mature weapon system,” General Fogleman said, but the C-17 exceeded requirements by a healthy margin in almost every category. During the review, the C-17 posted an overall launch reliability rate of ninety-nine percent. [See “The C-17 Makes Its Point,” October 1995, p. 38.]

Other Airlift Options

While all this was going on, however, credible alternatives to the C-17 were being readied by contractors Boeing and Lockheed Martin. Boeing offered the 747-400F heavy freighter (later to be called C-33 in Air Force parlance) that featured widened doors and hardened decks. Lockheed Martin offered the C-5D, an updated version of the venerable Galaxy, featuring improved materials, avionics, and engines. Other candidates originally had taken part in the competition to provide this so-called Nondevelopmental Airlift Aircraft (NDAA), but they had either withdrawn or been ruled out for technical reasons.

In the runup to the November decision, Washington was plastered with white papers arguing for this or that mix of C-17s and NDAAs. The regional commanders in chief recommended an all-C-17 buy, stating that it would offer them the most flexibility to deal with any contingency.

The Joint Chiefs of Staff, meanwhile, backed going with a mix of C-17s and 747-400s, seeing in this an adequate capability at a markedly lower cost than that of 120 C-17s. The savings, claimed the JCS, could be applied to other modernization efforts. In this, the chiefs drew the support of the Congressional Budget Office, which argued that a mix of seventy-two C-17s and thirty C-33s could provide adequate airlift with a life-cycle cost $9 billion lower than that of an all-C-17 fleet.

The contractors and members of Congress also threw reams of paper on the pile.

Once the decision had been made and announced, some critics returned to the CBO’s figure of $9 billion, maintaining that this cost differential is a “premium” the Defense Department will pay to get the advantages of an all-C-17 fleet. Secretary White, however, did not accept this assessment. “I don’t think of it so much as a premium,” he said. The all-C-17 purchase “was the lowest-cost option to meet the requirement.”

At the heart of the C-17 debate during the last two years lay a fierce controversy over the true size and nature of the US military airlift requirement. Moreover, translating that specific requirement into numbers-and types-of airplanes was a complex process.

Lowering the Bar

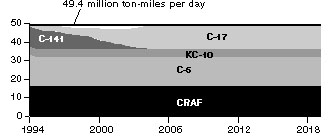

First, the Defense Department conducted an analysis to determine just how much lift would be required to carry out the postCold War national military strategy, that of supporting forces involved in two nearly simultaneous major regional conflicts. This analysis was called the Mobility Requirements Study/Bottom-Up Review Update (MRS BURU). This study determined that the old objective of transporting sixty-six million ton-miles of cargo per day (mtm/d) could be safely reduced to 49.4 mtm/d.

The previous level of sixty-six mtm/d “was predicated on [moving] ten divisions to Europe in ten days,” General Fogleman said. Since then, he added, “we’ve spent an awful lot of money on prepositioning” equipment aboard ships in the Middle East, “and we still have residual stuff in Europe.” The factors in combination “allowed us to reduce this overall requirement,” said the Chief of Staff. “Plus, the scenarios are just different.”

Once MRS BURU lift requirements were set, the Air Force, working with the Institute for Defense Analyses and the Office of the Secretary of Defense’s Program Analysis and Evaluation office, set out to make a more refined assessment. These organizations looked at how various mixes of aircraft would be able to handle this load and at what cost. This new study was called the Strategic Airlift Force-Mix Analysis (SAFMA).

“We then provided these results to industry for their review” and to help in the proposal process, said Gen. Robert L. Rutherford, commander in chief of US Transportation Command and commander of Air Mobility Command, Scott AFB, Ill. “Next we sat down with industry and negotiated ready-to-sign contracts for the C-17 and NDAA,” using those costs to compare the merits of each mix of airplanes.

Finally, officials conducted a Tactical Utility Analysis, “looking at the special features associated with short fields-the flexibility associated with intratheater kinds of operations and unit operations,” said Paul G. Kaminski, under secretary of defense for Acquisition and Technology.

The total take of information from these studies was provided in October to the DAB, which reviewed it for two days, using a variety of measures. Taken into account, said Secretary Kaminski, was DoD’s possession of “real . . . hard performance” data on the C-17 in tests and exercises, whereas it had only “performance predictions” for the C-5D and C-33. The C-17 at least reached the threshold-the bare minimum requirement-in all assessment categories and actually achieved the objective, or “desired” level of performance, in many of them.

Next to be looked at was the C-17 program’s schedule and cost progress. Officials found that, about seven months after “probation” was imposed, the actual program results started to match up with Air Force target costs and delivery schedules. At the time of the DAB deliberations, “the last ten deliveries in the program [had been] . . . made ahead of schedule,” Secretary Kaminski noted, adding, “We have a consistent and a predictable cost base now.”

Thus, the C-17 earned its way off probation and won the right to compete for the remaining lift requirement. The C-5D did not make the final cut because of its inability to operate from austere forward landing sites and short strips and other operational factors. Moreover, “It didn’t end up being a cost-effective option in the analysis . . . to reopen the line,” Secretary Kaminski said.

C-33 Pluses and Minuses

In the head-to-head C-17 vs. C-33 comparison, the C-33 enjoyed a number of advantages. It had a lower sticker price and needed no aerial refuelings to fly nonstop halfway around the world, whereas the C-17 needs several. The C-33 also had a major drawback: It could not operate from austere or short landing strips. In addition, it could not carry outsize cargo, such as tanks, Patriot missile systems, and other large items that would be critical in the early days of a war. The C-33 also lacked a roll-on/roll-off capability.

Finally, use of the C-33-which would mainly handle palletized cargo-could diminish the business available for the airlines participating in the Air Force’s critical Civil Reserve Air Fleet program. That, in turn might have caused some CRAF participants to withdraw from the program, drastically cutting the overall lift available in wartime.

About “a third [of the 49.4 mtm/d requirement] is provided by [the CRAF] . . . at a cost of just slightly over $200 million per year,” Secretary Kaminski pointed out. Were the Pentagon to purchase eighteen new C-33 freighters, he added, they would deliver “about 3.7 million ton-miles a day-about a fifth of what we get from the CRAF force. But the annual operating cost would be comparable or, in fact, slightly more. So it illustrates about the five-to-one leverage we can get with CRAF. . . . It’s something we want to maintain.”

For each mix of aircraft the DAB considered, it weighed the “CRAF impact,” and this factor was rated a “heavy” wherever a C-33 purchase was part of the mix.

“There are a number of CRAF carriers out there that perceive a commercial derivative airplane as being a threat to the business base, which we offer them to get them to commit to the CRAF program,” General Rutherford explained. Whether the threat is “real or not, they perceive that.” As a result, he said, he would have flown C-33s only about 600 hours a year-enough to keep Reserve pilots proficient-rather than risk CRAF pullouts.

One performance aspect that Secretary Kaminski said was a “key” factor in the C-17 decision was maximum aircraft on the ground (MOG). This has to do with “the ability to get into and move in confined spaces, and quickly on- and offload an aircraft.”

This ability to maneuver on a small ramp was one area in which the C-17 far outperformed its competitors, mainly because of its wingspan and ability to back up. This, in turn, translates into increased “throughput”-the amount of material delivered in a given period, with the available parking space.

“One can fit-and onload and offload-eight C-17s in an area that only three C-5s or 747s could fit in,” said Secretary Kaminski. In terms of throughput, there was a “slightly more than two-to-one advantage” for the C-17. He noted that CBO did not consider this MOG factor a major issue, though the SAFMA found it to be a highly telling discriminator.

“Unique” Requirements

The MOG and short/austere field capability are also vital in missions not covered in the lift study. General Rutherford explained that USAF faces “unique military airlift requirements” growing out of lesser regional contingencies, small military operations, humanitarian relief, brigade-sized airdrops, special operations, and intratheater lift.

Such missions, he said, require the utmost “flexibility, [which] is hard to quantify and model.”

Secretary Kaminski said that the defense acquisition panelists “very seriously” considered a mix of 100 C-17 and eighteen C-33 aircraft. Though the mix of C-17s and C-33s costs about one percent less in life-cycle costs than the all-C-17 buy, it brought far less flexibility with it, especially in light of the possibility that “we might lose some fields” to enemy seizure or chemical and nuclear weapons, he said.

In such cases, the C-5D and C-33 would be unable to operate close to the action, while the C-17 could. Korea is the hot spot with the most “sensitivity” to airfield loss, he added, and the all-C-17 buy offered “a more resilient force.”

When it flashed the green light for the C-17, the DAB laid in a big piece of the airlift puzzle. However, many questions are still open.

Purchase Rate. One is the rate at which the Air Force will procure its additional C-17s. The November decision led only to a contract award for the next eight-aircraft lot of transports. Secretary Kaminski said he will withhold until this June any final decision on whether to commit to a multiyear buy or even a faster production rate. The goal is to give McDonnell Douglas a chance to find more costs to cut, should a large commitment be offered. Typically, multiyear contracts yield cost savings because the work can be more precisely planned and paced. Potential savings might be “three to five percent,” Secretary Kaminski said. That would bring C-17s in for about $192 million apiece, compared to the early-lot cost of around $350 million each.

Secretary Kaminski said he will consider buying C-17s at rates ranging from eight to fifteen per year. As many as forty-six could be bought under a single multiyear contract.

At fifteen C-17s per year-the upper limit, because McDonnell Douglas has the facility to build up to that number-“you finish buying them two years earlier,” General Fogleman said. That, in turn, would diminish the duration of a gap in airlift capability now being felt because of the retirement of the C-141.

The “bottom out” point in airlift will come in about 2000, when airlift capability will dip to about forty-seven mtm/d.

Going Beyond 120. At some point, the Pentagon and the Air Force also will have to decide whether to increase C-17 purchases beyond the current level of 120 airplanes. Going beyond 120 would be “an outyear decision,” said General Fogleman, meaning that it would take place beyond the planning horizon of the current six-year defense spending plan.

The decision does not have to be made soon, but clearly Air Force officials are not ruling out such a move. “The primary advantage of building them at eight per year is you keep it in production longer,” General Fogleman explained, “and that gives you some options in the outyears to look at . . . whether you need more of them, or whether you start to use this basic airframe for other things.”

C-5 Replacement. Secretary Kaminski said the Pentagon has not yet decided whether a “stretched C-17” should be viewed as the front-running candidate to replace the C-5 Galaxy when early models of that airplane run out of useful service life in the next decade.

The Air Force took delivery of eighty-one basic C-5A aircraft between 1969 and 1973. A major modification of all the C-5As in the inventory took place in the mid-1980s, extending their service lives. In the late 1980s, the Air Force took delivery of an additional fifty C-5B aircraft. Today, the active and reserve components of the Air Force deploy 126 A and B models.

The oldest of these aircraft will begin to age out of the force not long after the turn of the century. One option would be to replace them with new-production C-5Ds. However, the C-5D’s low ranking in cost-effectiveness in the recent SAFMA suggests it would not be a strong contender to replace the C-5A and B models.

The C-5s may also be certified for certain kinds of low-level cargo drops, a requirement that even a 120-C-17 buy doesn’t cover. Should the C-5 be used extensively in this role, its structural fatigue would tend to accelerate and move up the date of its necessary retirement.

C-33s for CRAF? Secretary Kaminski said that, even though the DAB did not believe it made sense to procure the Boeing C-33 for the Air Force inventory, “we do want to . . . incentivize and enhance CRAF.”

Secretary Kaminski and General Fogleman ruled out buying CRAF-suitable aircraft for the airlines. The Air Force tried that before, with unpleasant results. USAF put money into specially modified 747s to be operated by Pan Am, with the proviso that they be available for CRAF in a call-up. However, when Pan Am went out of business, these aircraft were sold-many to overseas operators-and were lost to the program, although “we were able to recapture several of those,” General Fogleman said.

Secretary Kaminski said there will be CRAF enhancement studies, to be concluded sometime this spring or summer. Late last year, the program was still being defined, but General Fogleman said that in concept, “we would essentially finance . . . the development cost for someone to produce an aircraft that would be more attractive for the kinds of people who participate in CRAF.”

The money would go toward “making a more efficient 747 or MD-11,” or other widebody, the General said, such that there would be a smaller weight and cost penalty-or no penalty-for a carrier to buy airplanes with hard decks and other CRAF-suitable features.

But “we’re not going to go back into the subsidy business” of day-to-day airline underwriting, General Fogleman asserted.

The Tanker Fleet. In comparison with the airlifter force, the USAF tanker fleet is in fairly good shape. The service’s fifty-four KC-10s are expected to continue operating beyond 2020. Though the KC-135 airframe is chronologically old, it has relatively little wear, is still structurally sound, and could soldier on indefinitely.

The main obstacle to continued KC-135 service life is corrosion, the extent of which is extremely difficult to predict. Oklahoma City Air Logistics Center at Tinker AFB, Okla., is conducting an “Aging Aircraft Study” to determine what will become of such long-lived airframes as KC-135s, E-3 Airborne Warning and Control System aircraft, and B-52 bombers. It will yield initial results in 1997, and a definitive plan for managing the KC-135 fleet should be completed in 2000.

The first of the 500-odd KC-135 Stratotankers now in service should begin retiring in 2012, with a “KC-X” planned to reach service in 2013. Plans call for buying the new airplanes at a rate of fifteen per year-which some consider to be a highly optimistic assumption. Under this plan, 150 KC-Xs would be in service by 2021.

For now, Air Mobility Command is equipping KC-135s with rollers to give them a greater ability to deal with overflow lift requirements. They and the C-5s are receiving avionics upgrades and reliability improvements to make them more efficient and able to fly under automated civilian airspace management systems.

Defense officials caution that Congress has yet to weigh in on the new airlift plan. C-17 procurement could cost between $2.5 billion and $4 billion a year. Some lawmakers can be expected to push for a C-17/NDAA mix. Still, said Secretary Kaminski, the process provided “the most comprehensive analysis ever done on airlift requirements,” and the C-17 aced the test.

C-17 Performance |

|||||||

| Performance Category | Objective | Threshold

(minimum) | Current Status | ||||

| Payload (pounds over 3,200 nautical miles) | 130,000 | 110,000 | 131,000 | ||||

| Landing distance (feet, maximum payload) | 3,000 | 3,000 | 2,900 | ||||

| Backup capability (percent grade) | 2 | 1.5 | more than 3 | ||||

| Turns, unpaved area (feet for 180º turn) | 96 | — | 96 | ||||

| Rolling stock capacity (number of vehicles) | 15 | 15 | 15 | ||||

| Airdrop capability (number of paratroops) | 102 | 102 | 102 | ||||

| Airdrop capability (pounds of bundles) | 110,000 | 60,000 | 110,000 | ||||

|

USAF draws on all its resources to meet the goal of 49.4 million ton-miles per day. Those resources include the Civil Reserve Air Fleet and USAF’s KC-10s, each of which can carry more than eighty tons when operating as airlifters. |

Airlifters and Their MOGs |

|||||||||||

| Aircraft | Standard Payload | Maximum

on Ground | Cycles

per Day | Throughput Tons/Day | Increase in Tons/Day | ||||||

| C-5 | 65.0 | 3 | 7.4 | 1,443 | — | ||||||

| C-141 | 23.0 | 6 | 10.7 | 1,477 | 34 | ||||||

| C-33 | 73.1 | 3 | 8.0 | 1,754 | 277 | ||||||

| C-17 | 45.0 | 8 | 10.7 | 3,852 | 2,098 | ||||||

|

One performance aspect was maximum aircraft on the ground (MOG)-the ability to get into an airfield, move in confined spaces, and quickly load or unload. With its smaller wingspan and ability to back up, the C-17 far out-performed its competitors. The throughput of the C-17 was more than double that of its nearest rival, the Boeing C-33 freighter. | |||||||||||